In the manufacturing landscape, the integration of autonomy and robotics connectivity represents a paradigm shift, revolutionizing traditional production processes. This article explores the transformative impact of autonomy and robotics connectivity in manufacturing, examining its applications, benefits, and future implications for the industry.

The Evolution of Manufacturing: Manufacturing has undergone significant evolution over the decades, from manual labor-intensive processes to the adoption of automation and robotics. Today, the convergence of autonomy and connectivity is driving the next wave of innovation, empowering factories with intelligent systems capable of autonomous decision-making and seamless coordination.

Applications in Manufacturing

Autonomy and robotics connectivity are reshaping various facets of manufacturing operations:

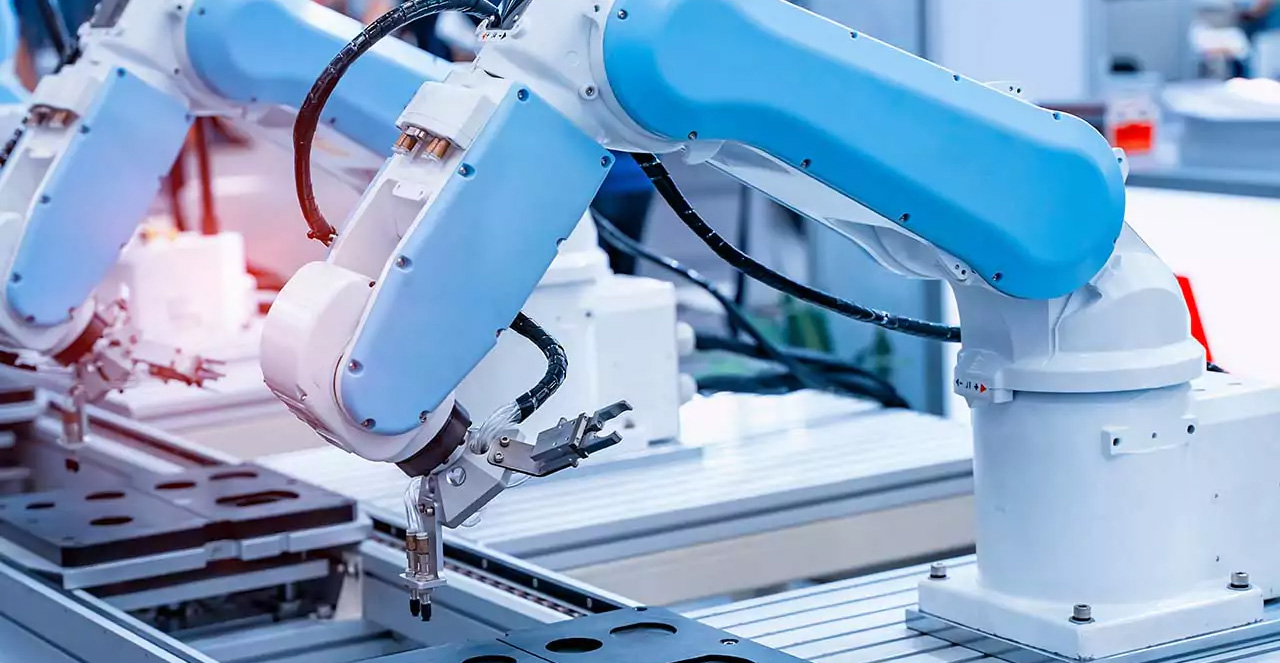

Automated Production Lines: Interconnected robotic arms and automated guided vehicles (AGVs) collaborate in synchronized workflows, assembling, handling, and transporting components with precision and efficiency.

Predictive Maintenance: Sensor-equipped machines and robots communicate real-time data to centralized systems, enabling predictive maintenance algorithms to anticipate equipment failures and schedule maintenance proactively, minimizing downtime.

Supply Chain Integration: Connectivity facilitates seamless integration of manufacturing processes with upstream suppliers and downstream distributors, enabling just-in-time inventory management, demand forecasting, and supply chain optimization.

Quality Control: Autonomous robotic systems equipped with vision sensors and machine learning algorithms inspect products for defects, deviations, and quality inconsistencies, ensuring adherence to strict quality standards.

Adaptive Manufacturing: Connectivity enables agile and responsive manufacturing systems capable of dynamically adjusting production schedules, configurations, and parameters based on real-time demand signals and market fluctuations.

Benefits of Autonomy and Robotics Connectivity: The integration of autonomy and robotics connectivity offers several benefits to manufacturing operations:

Enhanced Efficiency: Streamlined workflows, optimized resource utilization, and reduced cycle times result in increased productivity and throughput.

Improved Quality: Real-time monitoring, predictive analytics, and automated inspection processes enhance product quality and consistency, reducing defects and rework.

Cost Savings: Reduced labor costs, minimized downtime, and optimized resource allocation contribute to overall cost savings and improved profitability.

Safety: Autonomous systems and robots handle repetitive, hazardous tasks, mitigating the risk of workplace accidents and ensuring a safer working environment for employees.

Flexibility: Agile manufacturing systems capable of rapid reconfiguration and adaptation enable manufacturers to respond promptly to changing market demands and production requirements.

Challenges and Considerations

Despite its transformative potential, the adoption of autonomy and robotics connectivity in manufacturing presents several challenges:

Investment Costs: Upgrading existing infrastructure and implementing connectivity solutions require significant upfront investment in technology, training, and infrastructure.

Integration Complexity: Integrating disparate systems, platforms, and devices into a cohesive ecosystem poses technical challenges related to interoperability, compatibility, and data synchronization.

Cybersecurity Risks: The interconnected nature of manufacturing systems increases susceptibility to cybersecurity threats, necessitating robust cybersecurity measures to safeguard sensitive data and intellectual property.

Workforce Transition: The deployment of autonomous systems and robotics may necessitate workforce upskilling and reskilling initiatives to equip employees with the necessary skills to operate, monitor, and maintain connected manufacturing systems.

Regulatory Compliance: Compliance with industry standards, regulations, and safety protocols is essential to ensure the legality, integrity, and safety of autonomous manufacturing operations.

Future Perspectives

As technology continues to advance, the future of manufacturing lies in the seamless integration of autonomy and robotics connectivity. Advancements in artificial intelligence, machine learning, and sensor technology will fuel the development of increasingly intelligent, adaptive, and interconnected manufacturing systems. Moreover, collaborative research initiatives, industry partnerships, and cross-sector collaborations will drive innovation and accelerate the adoption of autonomy and robotics connectivity in manufacturing.

Conclusion

The convergence of autonomy and robotics connectivity is reshaping the manufacturing landscape, ushering in an era of unprecedented efficiency, quality, and agility. By harnessing the power of intelligent, interconnected systems, manufacturers can unlock new opportunities for innovation, growth, and competitiveness in an ever-evolving global market. Embracing autonomy and robotics connectivity is not merely a choice but a strategic imperative for manufacturers seeking to thrive in the digital age.